HANDLING OF TEST ITEMS

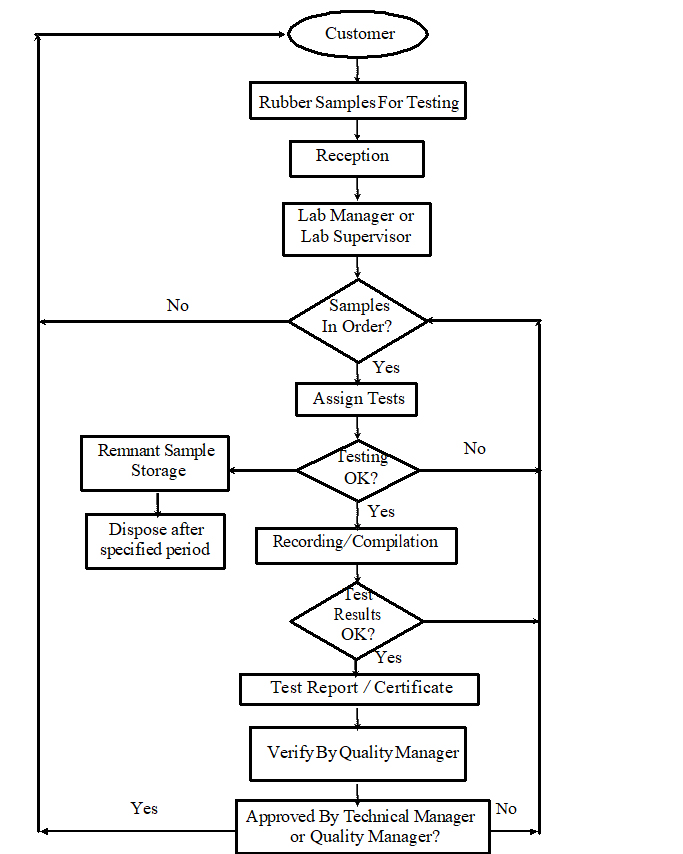

MCL is operating a system of handling test items such that their identification and traceability shall be unambiguous. Internal validation of test items and results obtained shall be incorporated at various stages.

The Lab Manager (LM) / Lab Supervisor (LS) has the overall responsibility for handling of test items. The test items are marked and preparation of work instruction and identification of testing staff will be done with the assistance of the Assistant Lab Supervisor.

All samples received for testing are checked for producer/customer id., lot identification with lot no., sample no., grade required, production date, sampling date, tests required and customer’s reference no. The checked samples are registered in computer programme and arranged for testing. Each lot is uniquely identified with serial no. by using computer print out labels. The LM/LS is to plan testing and distribute work to various staff.

Samples which are abnormal in appearance is to be segregated and noted in the Anomaly Book for appropriate action to be taken later.

All remnant samples is kept at a designated place for at least one month before disposal with authorisation from LM/LS.